Tunnel blast freezers

Rapid chilling

Perfect preservation

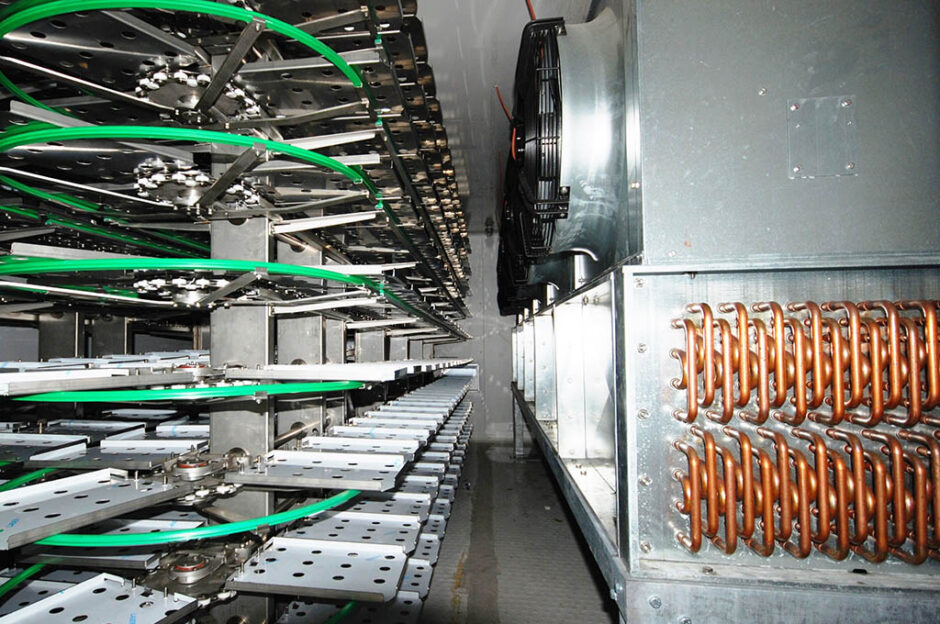

Madefrigor designs and builds industrial refrigeration systems for the food industry and beyond: tunnel blast freezers reaching temperatures of -45 °C (static or automatic); meat, cured meats and cheese ageing rooms; frozen/cold storage rooms; and air handling units for food processing rooms.

For example, the butchery tunnel blast freezers are created to chill meat after slaughter or after cooking according to the predetermined timescales required by the customer to safeguard the organoleptic properties and the hygiene of the products. Each project is customised in order to fully satisfy the customer’s expectations and offer maximum performance.

Custom

cold rooms

Cold rooms

Frozen storage rooms (cold rooms) are ideal for pre-refrigeration (essential for the meat sector), refrigeration, freezing and deep-freezing. In light of their intended purpose, they are built with 200 mm thick panels.

Madefrigor designs and installs both small and large systems, including direct expansion cold rooms with freon or ammonia and direct expansion cold rooms with CO2. Medium temperature cold rooms are also available with freon direct expansion systems or glycol systems. Whenever possible, we use natural refrigerants such as ammonia, propane and CO2, as they are environmentally friendly and have low operating costs.

Blast freezing: first solution

Ceiling-mounted cooling unit sized according to the thermal characteristics and the quantity of meat to be cooled, in addition to the timescale required by the customer. Cooling can be provided by way of an autonomous refrigerator or a centralised system (ammonia, CO2, freon).

Blast freezing: second solution

Stainless steel air handling unit containing a cooling coil, a defrosting system and a centrifugal fan: the air is evenly distributed in the room with the suitable characteristics (speed, temperature) according to the meat to be chilled.

Cooling and freezing

After the blast freezing process, cold rooms can be used to store frozen meat for long periods. The refrigerant can be CO2, freon or ammonia, with an evaporation temperature of -30 °C/-35 °C, to obtain an ambient temperature of -20 °C/-25 °C.

An efficient system allows for rapid chilling to protect the properties and taste of the meat.

Contact us nowOur customers

All the companies that have chosen Madefrigor as their refrigeration partner

The Madefrigor/CTM headquarters are located in Rovello Porro (Como), there is also a Madefrigor/CTM operational headquarters in Brugine (PD).

now