Cold rooms for the meat industry

High-tech solutions

for the meat sector

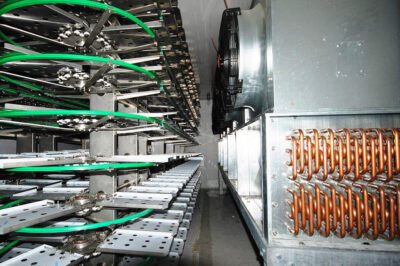

Specialising in industrial refrigeration, Madefrigor manufactures systems for all areas of the agriculture and food industry. For the meat and cured meat sector, we design and create cold rooms, pre-freezing and blast freezing rooms, and tunnel freezers. We also specialise in air conditioning for meat processing rooms that require particular attention in terms of air handling and filtration.

Meat storage requires advanced technological solutions to avoid any decay, ensuring that the organoleptic properties of the product remain intact. The diverse skills of the Madefrigor team allow us to design custom systems that are tailored to the specific needs of each meat product and meet customer expectations.

Refrigeration units for the food industry

Systems to meet

every need

We create refrigeration units for large-scale enterprises in the food industry, i.e., centralised cooling systems with a single refrigeration unit to chill the refrigerant (refrigerant gas, ammonia, glycol/water). Our dedication to the environment is reflected in our use of natural refrigerants, low environmental impact, and energy-saving solutions. Explore the options by clicking on the table at the side.

Increasing the relative humidity to 90–95% helps to counteract weight loss.

Cold room humidity

Depending on the chilling procedure for butchered meat, there is a risk of losing up to 3% of the total weight, which negatively impacts the company’s profitability.

Our butchery cold rooms are designed and manufactured to maintain the perfect balance between the ideal meat storage temperatures and a relative humidity equal to/greater than 90%, in addition to improving the thermal conductivity of the air. Madefrigor’s technology combines experience with technological solutions to optimise food storage and processing.