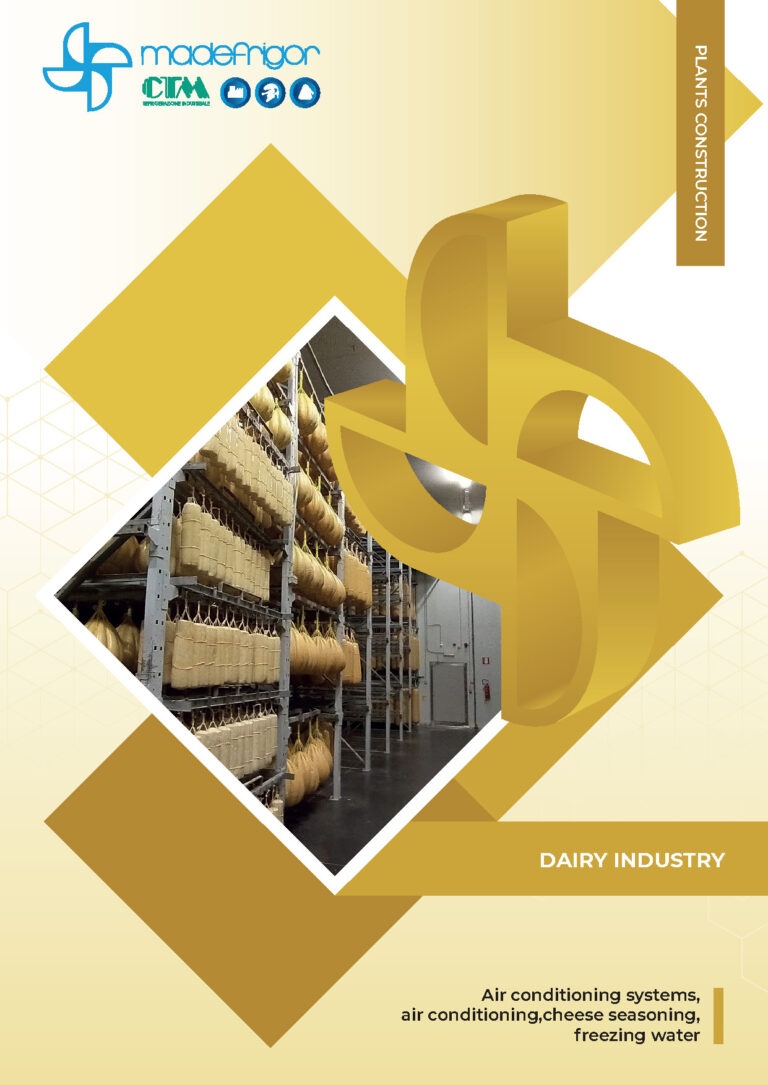

Cheese ripening systems

Flawless ripening

Madefrigor, an industrial refrigeration specialist, is very active in the dairy industry. For the past 50 years, we have been designing systems for cheese processing and ripening, sanitisable air conditioning systems, drying systems and refrigeration units. Backed by expert knowledge and a team of specialists who are extremely familiar with the hygiene/sanitary issues and variables that influence the biochemical reactions of milk processing, we are able to offer a wide range of options. The ripening process determines the structure of the cheese; its appearance; its composition, i.e., the ideal humidity level and correct amount of salt; and the intensity of its aroma and flavour. It is therefore essential to entrust the management of the various ripening components to Madefrigor, a company capable of producing innovative and effective systems: we will take responsibility for each phase of the project, from its inception to final testing.

Perfect results

every time!

Cheese ripening systems

Ripening gives cheese its distinctive appearance, flavour and aroma. The temperature, humidity, ventilation and ripening time therefore all play a vital role in the creation of a flawless cheese with the desired organoleptic characteristics. Following the correct procedure before drying and ripening ensures the correct water and salt content, low acidity, and inhibits the development of pathogens. Perfect results every time!

Madefrigor designs and builds industrial refrigeration systems to meet every cooling need, in addition to providing 24/7 full-service support for any malfunctions or unexpected issues related to your system. Cooling issues? Madefrigor has the solution.

Hard cheeses

Cheeses that are ripened for a long time (over 9 months) require temperatures over 12 °C and environments with less than 90% humidity to create a hard and compact rind.

Soft cheeses

For soft cheeses (maximum 60 days), temperatures between 2 and 8 °C and environments with humidity levels above 90% are ideal for preventing the formation of a thick and solid crust.

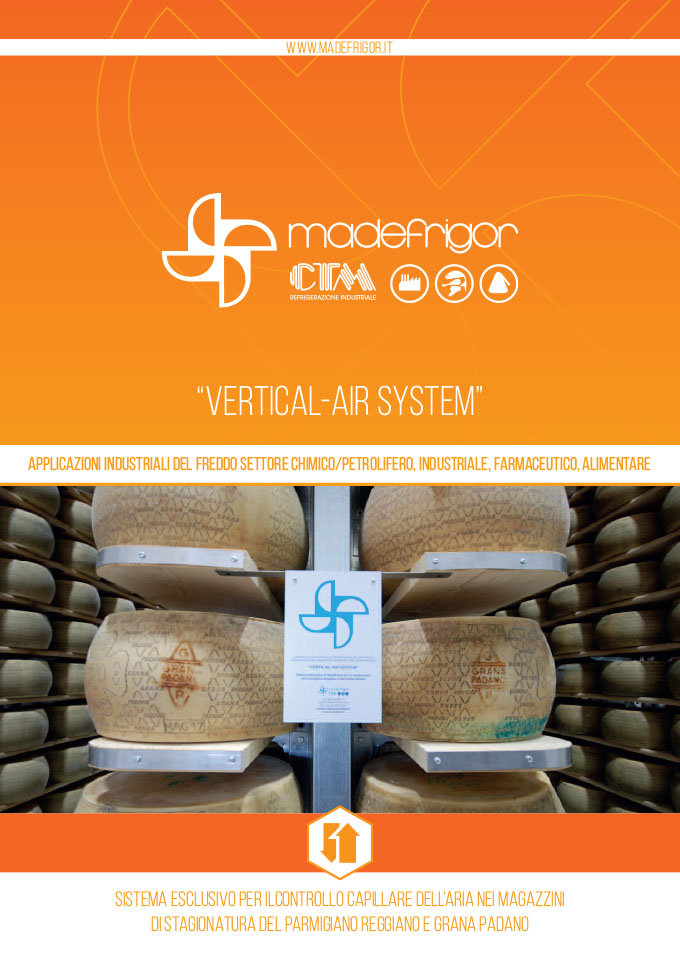

A revolutionary system

Madefrigor developed the Vertical Air System, a revolutionary system for ripening Grana and Parmigiano Reggiano, to overcome the problems posed by traditional refrigeration systems.

Temperature, relative humidity and ventilation: Madefrigor knows ripening inside and out.

Contact us now

Diary web brochure

Are you interested in Madefrigor's cheese ripening systems and warehouse air conditioning systems?

Vertical air system brochure

Are you interested in Madefrigor's technology to create perfectly ripened Grana and Parmesan?

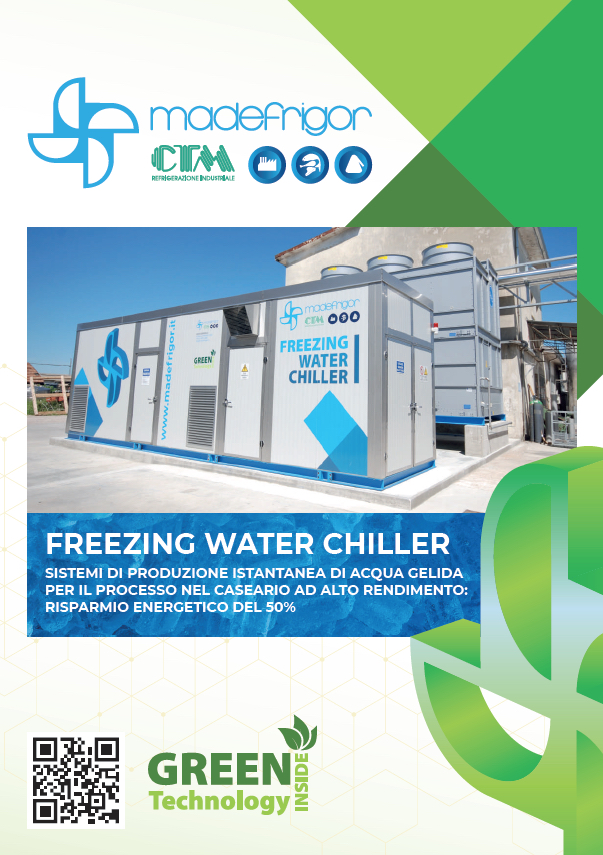

Freezing water chiller

Download the brochure to discover all the features of our chilled water production systems

Our customers

All the companies that have chosen Madefrigor as their refrigeration partner

The Madefrigor/CTM headquarters are located in Rovello Porro (Como), there is also a Madefrigor/CTM operational headquarters in Brugine (PD).

now