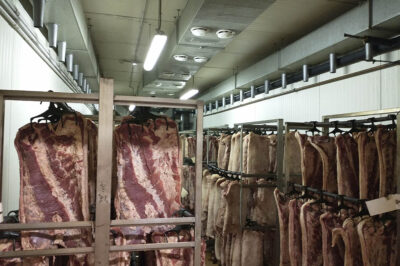

Cured meat drying system

High-tech solutions

for the cured meat sector

Specialising in industrial refrigeration for the food industry, Madefrigor provides the best design solutions, manufacturing systems for drying cured meats and much more. In the cured meats sector, the company offers cooling management for ageing cured meats, processing plants for prosciutto and speck, and ovens for cooking mortadella. Like all of our products, our systems for drying cured meats are also customisable. Our specialist team, made up of experienced technicians from a variety of backgrounds, can guarantee flawless final results and offer 24/7 full-service maintenance support 365 days a year.

Cured meat drying system

Custom products to suit every situation

To meet the needs of meat and cured meat producers, Madefrigor has designed a wide range of options: modern systems for drying cured meats, entire lines dedicated to the different stages of curing, processing systems for prosciutto and speck,and ovens for cooking mortadella. When it comes to systems for cured meats, our experience in the field of industrial design and construction allows us to offer numerous design variants, including solutions with static evaporators or cooling systems and compact, pre-assembled and tested monobloc systems. For curing chambers, we can install AHUs that alternately manage 2 or 3 rooms (one at a time) with different process programmes.

Flavour, aroma, consistency: ageing is crucial for quality cured meats.

The good cold for salami and speck

Building on 50 years of experience and intensive research, Madefrigor has a wealth of technical skills in the diverse world of cooling. We can offer systems that are tailored to the specific needs of any type of cured meat, combining excellent performance with a low environmental impact and low energy consumption, in compliance with hygiene and commercial standards.

For example, pre-ripening, drying and curing are all fundamental phases, allowing prosciutto and salami to acquire the right texture, flavour and unmistakable aroma. Only proper temperature and humidity management can create a satisfactory final product.